Processes

Made in Tuscany

The product manufacturing process, in both its primary and post-production finishing phases, takes place entirely in the heart of the company.

Our operators carry out quality control on every single unit. The work of CTS Design represents a perfect combination between industrial production, which guarantees speed and precision, and the craftsmanship of wood, marble and upholstery, which emphasises attention to details. Our ambition is to guarantee exclusively ‘Made in Italy’ products, selecting suppliers with particular care and searching for high quality materials, favouring local producers and benefiting from a local supply chain. For example, the only external processes required, such as the melting of aluminium, the moulding of fibreglass nylon (albeit on CTS owned moulds), the purchase of foam rubber for upholstery, and the chrome plating, are carried out by third-party suppliers who are not just Italian, but Tuscan, that is why we talk of ‘Made in Tuscany’.

Upholstery

Upholstery has always been accompanying the company in the production and manufacture of seats, cushions, bed heads and various upholstered items using high quality leathers and fabrics.

The primary objective is to fully satisfy customer requirements also by realising tailor-made projects, with a high focus on design and attention to detail.

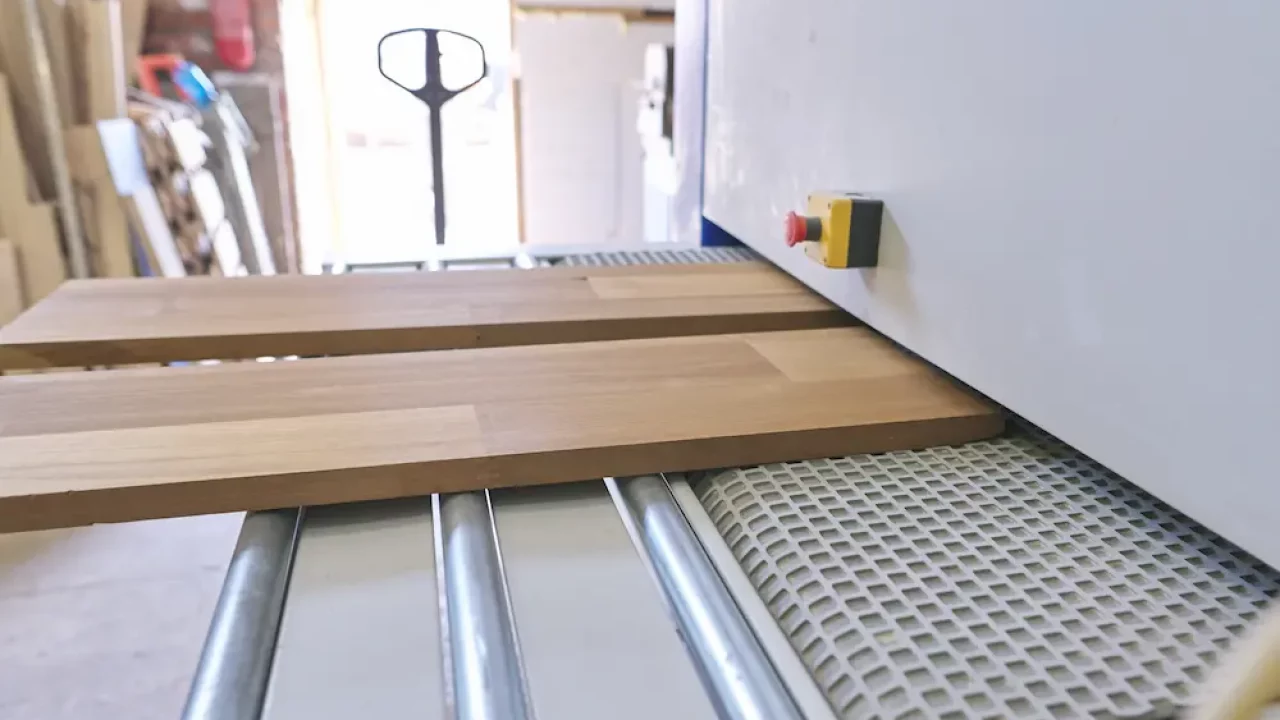

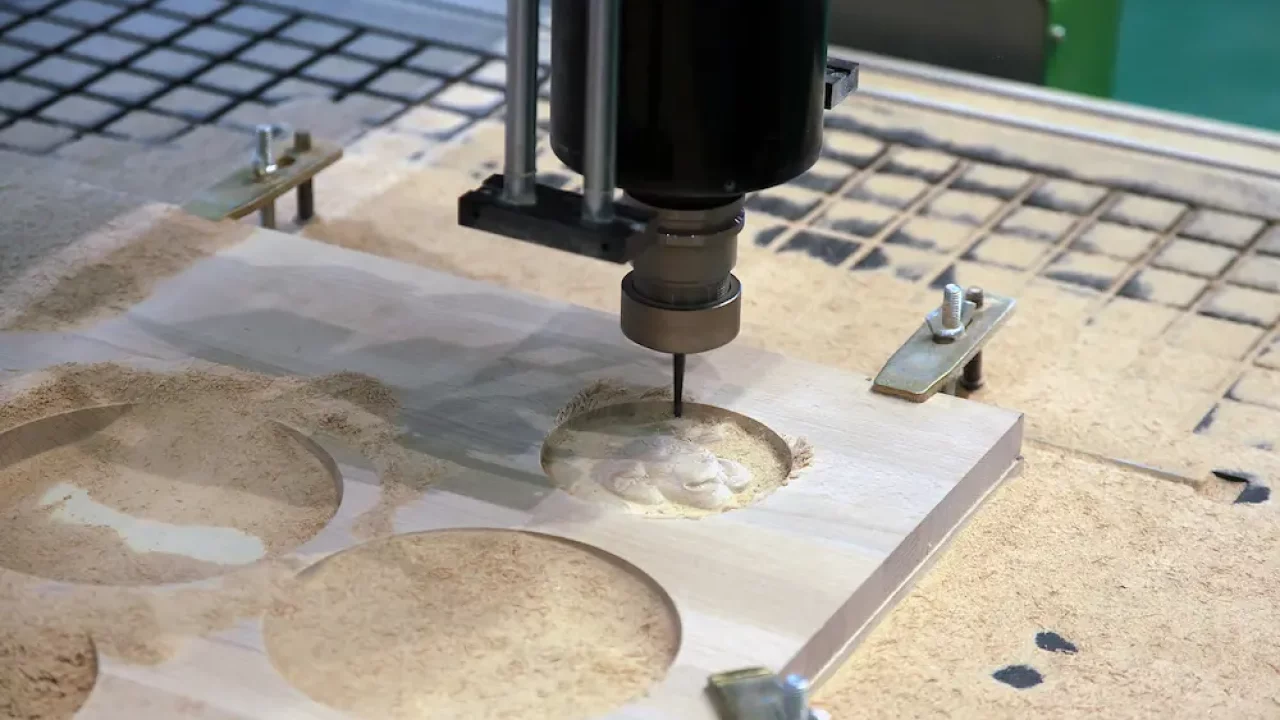

Carpentry

The carpentry is dedicated to the production of frames and supports for the furnishing complements in the catalogue and according to the customer’s design. Thanks to the presence of several equipments it is possible to process and shape various materials such as mdf, birch plywood, marine plywood for outdoor furniture, as well as valuable materials such as solid oak.

In addition to the use in semi-finished products, the carpentry department is an important resource for the post-production phase by supporting the packaging process of crates, pallets and multipallets, to guarantee the safety of the products during transport, also for overseas shipments.

Painting

The painting plant, which also plays a leading role in the production process of most of the collection, consists of several pressurised booths, a drying room and automatic sanding machinery; this equipment makes it possible to treat a variety of materials and surfaces starting from the raw semi-finished product to the desired finish.

In particular, painted materials include: wooden table tops made by the carpentry, table and chair bases in cast or die-cast aluminium alloy, lacquered in gloss or matt, wooden, nylon and moulded fibreglass chair shells are also painted in liquid laminate or other finish to customer request

Also thanks to this department it is possible to customise in colour and finish all products

Marble and Ceramics

The marble and ceramics workshop processes slabs of natural stone rigorously selected and approved at the quarry. The operators usually process slabs of Carrara marble or other precious marbles such as Calacatta oro and arabescato from Carrara, as well as other types of coloured marble such as Marquinia and Emperador selected in Spain.

In addition to marble, the plant boasts a dedicated line for cutting and shaping 20 mm thick ceramic tiles of the well-known leading brands DEKTON and Laminam.

All processed slabs are trimmed either to standard size or according to specific customer requirements.

Download the complete catalogue